Jeder Reiter wünscht sich das beste Preis-Leistungs-Verhältnis-und das natürlich gerne zu dem geringsten Preis. Es ist nun mal nicht fremd, dass der Reitsport sehr kostspielig ist und man bereit sein muss, in sich und sein Pferd ordentlich zu investieren. Jedoch ist es klar, schnell verfügbar und günstig ist verlockend.

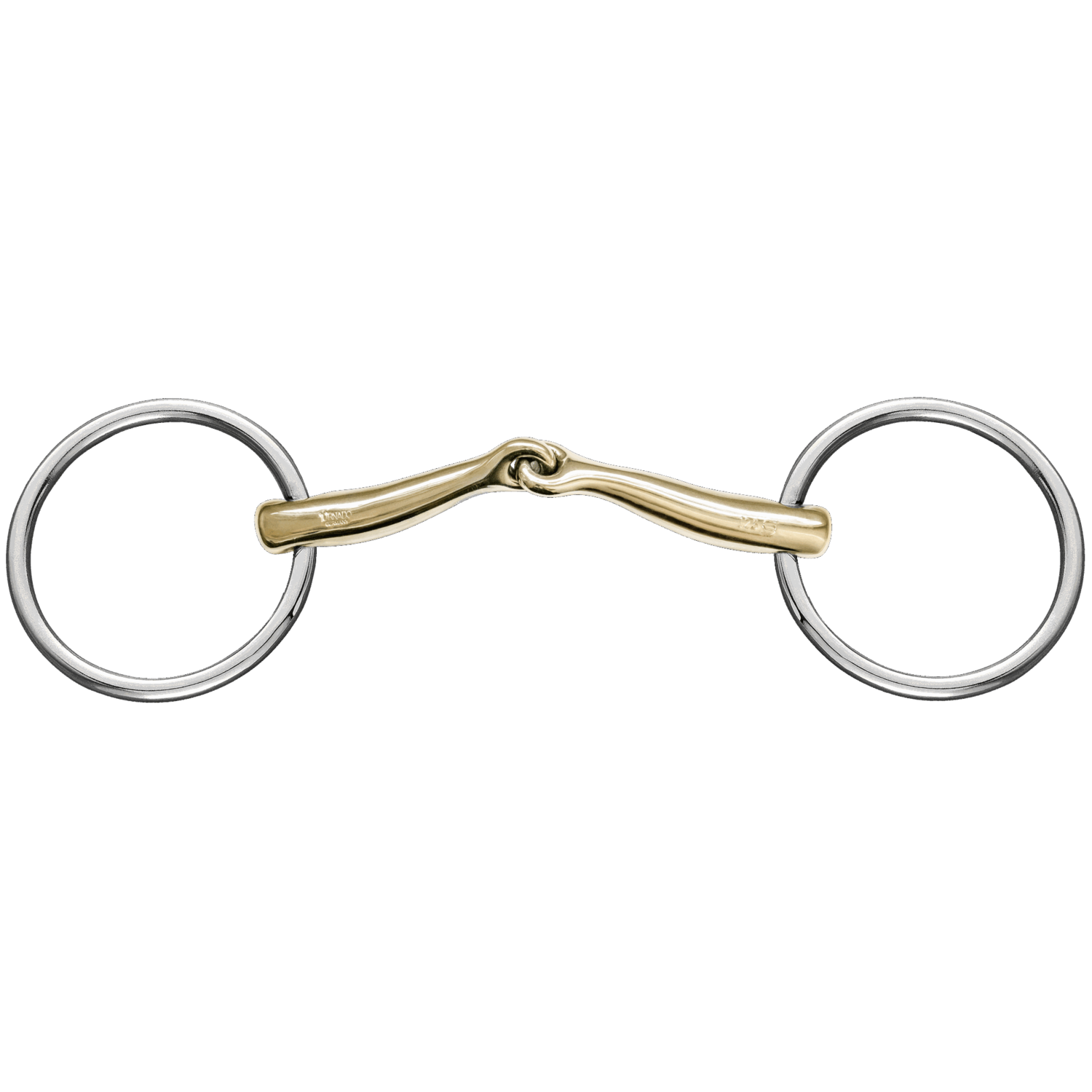

Auf dem ganzen Markt werden einem reichlichst verschiedene Gebisse angeboten-mit hohen Preisschwankungen-welche sich meist in ihrer Qualität unterscheiden. Doch welche Unterschiede treten auf?

In dem heutigen Beitrag klären wir Euch über die Qualitätsunterschiede bei Gebissen auf.

The bit quality differs in terms of material

When it comes to the material, there are rubber, plastic or metal, or even Stainless steel or special alloys like Aurigan. Specifically with alloys there are big differences, even though you can’t see them directly, like for example if the bits are nickel-free.

It also is important, to check if the material is free from solvents and softeners, to prevent health risks for your horse.

You can find all the information and basic features of the different materials here: All about bit materials.

Why processing is crucial for bit quality

Good material is still not a good bit yet, because the actual quality depends on how the material is processed.

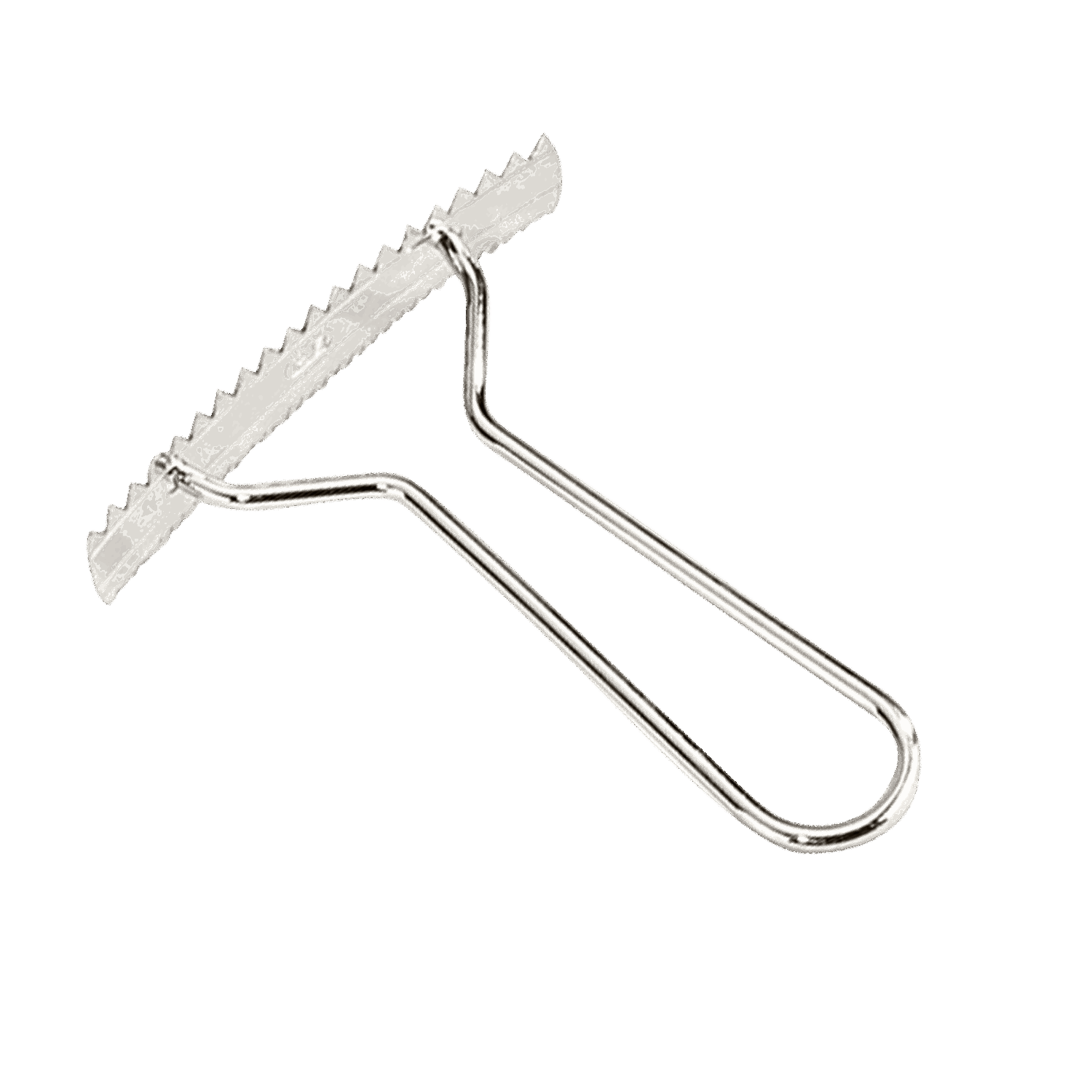

Plastic- and rubber bits

Plastic- and rubber bits have the shortest lifetime of all materials. That’s apparent.

However, it makes a difference whether or not your plastic bit shows cracks and

that your horse could even swallow in a worst case scenario after only a few months.

In addition it is recommended for your bit to have a steel soul, to prevent it from being bitten through completely.

Stainless Steel

Stainless Steel is in its first-class edition rust-free and often lasts for over 10 years or even a horse’s lifetime.

If the stainless steel has been processed poorly by using for example less chrome, it will rust after a short time or form sharp edges. Nickel can also be worn off. Ultimately, we are not talking about a long working life here. What remains is usually 1-3 years.

Aurigan bits

Aurigan was the first bit material on the market that is nickel-free and has been tested for toxicity. The main component of this material is copper. Silicon and zinc are added as alloys.

The main feature of this material is that it stimulates the chewing activity of the horse. This happens through the high percentage of copper in the material. This high percentage leads to a natural oxidation process and has a positive effect on the horse. We as humans can smell the odor of the Aurigan and the horse can taste it of course. The taste of Aurigan stimulates the salivation in horses.

It should also be noted that Aurigan is a material that requires a lot of care due to its high copper percentage, as bits made from this special alloy feel softer than stainless steel. This is not necessarily a bad thing, but it means that the longevity between high-quality and inferior Aurigan bits can vary a lot, depending on how the materials are processed and used.

This is because a high copper percentage in the material of the bit does not automatically mean that natural, good oxidation will occur, which is necessary for the increased saliva flow, less expensive bits are often made from simpler materials, which

contain (among others) aluminum.

The bits are no longer oxidizable due to the aluminum and the Saliva-stimulating property gets lost.

As a rule, inferior processing can cause the joints to loosen or the mouthpieces to deform.

SENSOGAN the evolution of Aurigan

Despite the popularity of Aurigan, SPRENGER has further developed the special alloy.

SPRENGER has changed the ingredients so that less copper is required, together with zinc and manganese. The Chewing activity is supported even more specifically.

In addition, SENSOGAN bits are now easier to care for than their predecessors and therefore retain their color for longer.

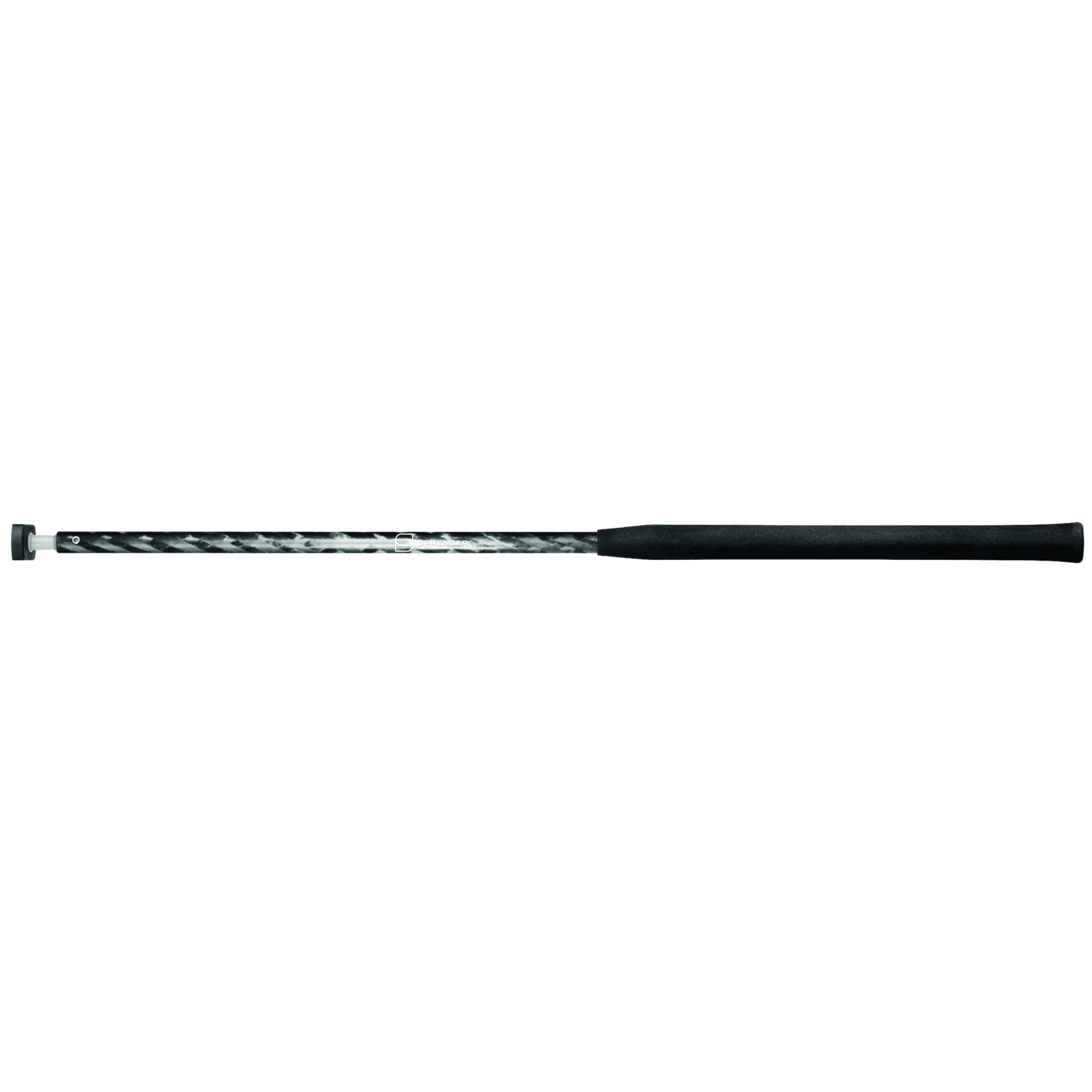

Bit processing and shaping

There are also noticeable differences in quality when it comes to the shape of the bits. There are many types that have different effects on the horse, as well as side pieces that influence the effect of the bit. In terms of quality, it’s important to pay attention to the processing.

Make sure, for example, that there are no sharp edges anywhere and that the joints are

smoothly sanded. The transitions between the bit and the side piece should also be smooth.

The possible

consequences of poor bits

A not precise process often leads to pressure points or an incorrect position in the mouth.

If the sidepieces of a bit or the joints are uneven, the bit will sit crookedly in the horse’s mouth. Pressure points are often a form of side effect of this, or the bit may even slip during riding. If the bit doesn’t fit correctly, this leads to discomfort in the mouth. Sharp edges cause injuries, and the horses’ health can be impaired by pollutants, or it may react with allergies to inferior materials used. In addition, therideability also suffers because the communication between horse and rider gets disturbed.

How can I tell if a bit is of the right quality

for my horse?

It’s easy to tell if the bit is of the right quality! You know what material has been used and in what composition (ideally, the bit was manufactured in Germany), and you can recognize high-quality processing. This means: no unevenness or sharp edges on the bit and side pieces. With plastic bits, you should make sure that there is a continuous connection (not screwed!) to ensure safety and prevent injuries in the horse’s mouth. Plastic or rubber should be free of softeners and solvents.

Your horse accepts the bit without any problems, chews relaxed and responds appropriately to rein aids? These are good signs that your horse is also satisfied with the quality of the bit. A slight foaming in the mouth can also be a sign of relaxation.

How can I tell if the quality of my bit is

sufficient?

You can determine whether the quality of your bit is too low for your horse by observing the following signs:

There are visible irregularities or sharp edges on the side pieces and mouthpieces. Plastic mouthpieces may be screwed together and not have a continuous connection or may contain softeners/solvents.

Your horse can also show you that it is unhappy with its bit by showing the following signs:

There are visible pressure marks in the horse‘s mouth and abrasions on the tongue, palate or on the corners of the mouth. Your horse refuses the bit, clamps its jaw shut and shows head shaking.

But be careful! These can also occur if your horse does not have the right bit. You can find out how to determine the perfect size for your bit here: How do I find the right bit?

So check your bits for cracks or damage.

Price differences depending on quality.

A low price often breaks down quickly.

No matter in what field, we all naturally tend to go for the cheaper products. Some of you may have heard the saying, “If you buy cheap, you buy twice.” The result of inferior quality: wear and tear in no time, lack of safety, the horse is unhappy, and you soon must buy a new one again.

SPRENGER bits- more expensive than others?

Maybe most of you have already noticed that the SPRENGER bits usually cost more than cheaper brands from other manufacturers. Is this just because of the brandname? Or is there more to it than that?

We have the answer: It is because SPRENGER stands out in one crucial aspect: quality and durability.

SPRENGER bits are made of solid material; even most plastic bar bits have a steel core, and rubber bits have a rubber-coated Stainless-steel core.

Our specially developed alloy also has its price-SENSOGAN bits

As mentioned, SENSOGAN is a further development of the AURIGAN alloy, which we also developed, it consists of a reduced copper percentage, together with zinc and manganese, and is nickel-free.

If you would like to learn more about SENSOGAN, please visit our blog post: Chewing

promoting SENSOGAN bits from SPRENGER

To achieve this more complex work steps are necessary. They make the material more expensive and are the cause of the price increase for Aurigan and SENSOGAN bits, in contrast to bits that are made of stainless steel for example.

The price difference is also explained by the fact that we place a lot of importance on development and precise manufacturing.

Conclusion: Why quality is crucial when it comes to bits

Even though we all want to save money, a bit is directly connected to the horse mouth. That’s why it’s worth it to invest in good quality. Your horse will be grateful for it.